Bioenergy with Carbon Capture and Storage (BECCS) could play an important role in meeting the UK’s net zero emissions target according to the sixth carbon budget scenarios. However, there are many different ways BECCS could be deployed in the UK, and how that roll out is managed could make a big difference in terms of how much of a role BECCS plays in the UK net zero ambitions. In this article, Dr Muir Freer, Dr Clair Gough and Dr Andrew Welfle, from the Tyndall Centre, outline the model they created to help the deployment of BECCS for the UK to meet net zero and help ensure the roll-out of low-carbon supply chains.

- BECCS supply chains must be carefully sited and integrated into their wider infrastructural, geographical, economic and social landscapes to ensure their low-carbon deployment.

- The mixture of transportation methods available for BECCS supply chains should be carefully modelled to ensure they can be connected to geological storage.

- Modelling for BECCS supply chains enables us to understand its future performance under changes in factors such as biomass insecurity and transportation decarbonisation.

BECCS and Net Zero

BECCS is an important Carbon Dioxide Removal (CDR) technology, which consists of the combustion of biomass ranging from agricultural residues to industrial wastes and energy crops while producing biofuels, power and hydrogen, and capturing the emissions and securely storing them below ground. The technology is considered key to achieve net zero as it has been projected to remove up to 96.5 MtCO2 per year within the UK by 2050 depending on the scenario.

Some areas of the UK are better suited for certain configurations of BECCS supply chains depending on their access to biomass, geological storage, their energy users and low-carbon transportation infrastructure. For example, agricultural residue derived BECCS-Power supply chains are well suited for the Humber cluster, while BECCS-Waste-to-Energy supply chains are well suited for the North-West cluster.

Moreover, some areas are better suited to support large-scale BECCS facilities than others hence the importance of determining the optimal BECCS facility scale. For example, the average optimal facility scale of a wheat straw derived BECCS-Power supply chain ranges from 0.87 to 1.38 MtCO2 per year in the Humber region and 0.59 to 1.09 MtCO2 per year in North Wales.

We created the Carbon Navigation System (CNS) model and Biomass Repository to aid decision making for policymakers and industry to better organise and plan the implementation of BECCS for the UK to meet net zero more sustainably.

How does the model work?

Say you wanted to go to the cinema, Google Maps would tell you to walk for 5 minutes, take a bus for 20 minutes and then walk for a further 5 minutes to reach your destination. The CNS model works in a similar way, but where Google Maps optimises transportation times for people, it optimises CO2 transportation emission for BECCS facilities.

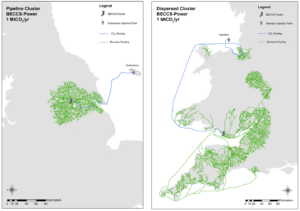

For any industrial cluster or dispersed location in the UK, the model can simulate the transport characteristics of any BECCS supply chain while automatically switching between pipeline and non-pipeline transportation methods to minimise emissions. For example, the same wheat straw derived BECCS-Power supply chain calibrated to capture 1 MtCO2 per year has been simulated in two different locations in the diagram below, where the supply chain transportation emission are 7.6 times greater in the dispersed cluster siting location compared to the pipeline cluster location.

Simulation of a wheat straw derived BECCS-Power supply chain calibrated to capture 1 MtCO2 per year simulated within a pipeline cluster location and a dispersed cluster location.

The Biomass Repository was developed alongside the CNS model, as a high resolution database which details where the biomass types are and what the potential resource is at each site. When this database is integrated into the CNS model, the model can search for a specific quantity of biomass at a chosen BECCS facility location, and will estimate transportation emissions for the selected site.

From that same location, the model can calculate how much CO2 can be captured from the biomass and will calculate the route for the facility to be linked up with one of the industrial CCS clusters to securely and permanently store CO2 offshore. Any energy or fuel generated by the facility can also be transported to its users or energy storage method, such as integration with the national grid.

Moreover, the supply chains can be modelled under certain biomass security scenarios – an increase in competition from other sectors for biomass supply, the closure of domestic biomass suppliers, biomass supply shocks from heatwaves and droughts and increased competition from other domestic or international BECCS supply chains – to determine the impact on their carbon performance. For example, a 50% decrease in biomass yield would result in an average 5-10% increase in transportation emissions for BECCS supply chains in the UK.

The model can be repurposed to model any CCS or other supply chain (bio-chemical, glass, cement and energy sectors, for example). It is especially suited for connecting different emitters across the UK to geological storage sites and was designed to plug into any life cycle analysis to reduce transport emissions and better base their analysis in reality.

Aiding decision making

The CNS model can reduce the uncertainty in the multitude of factors which can impact the deployment potential of BECCS for the UK to meet net zero, including optimal sitting locations, optimal facility scales for specific areas in the UK, the impact of biomass security and the impact from the decarbonisation of the transport sector.

The analysis will allow policymakers, academia and industry to identify and quantify the impact on the carbon performance of BECCS supply chains for the major sources of uncertainty for BECCS deployment and help improve potential deployment pathways and roadmaps to achieve net zero sustainably.

A greater understanding of the prioritisation of transportation decarbonisation pathways for BECCS supply chains can be gained from the CNS model scenarios. For example, transitioning to a high degree decarbonised HGV fuel like green hydrogen (8gCO2/t-km) would result in a 73-74% decrease in BECCS supply chain transportation emissions for the UK, indicating that the decarbonisation of HGVs within BECCS supply chains have the greatest potential carbon savings as the integration of high degree decarbonised fuels into shipping and rail reduce transportation emissions by 35-36% and 29-33%, respectively.

Policy recommendations

- The CNS model and Biomass Repository aids decision making for policymakers and industry by simulating BECCS supply chains over a wide range of locations to determine their carbon performances across the UK.

- BECCS supply chains must be carefully sited and integrated into their wider infrastructural, geographical, economic and social landscapes to ensure their low-carbon deployment.

- To account for these multiple factors, we have developed a model which determines the location enabling the least carbon emissions throughout the entirety of the supply chain while determining the optimal facility scale and accounting for different biomass security scenarios.

- Importantly, results indicate that the decarbonisation of HGVs within BECCS supply chains have the greatest potential carbon savings.

Policy@Manchester aims to impact lives globally, nationally and locally through influencing and challenging policymakers with robust research-informed evidence and ideas. Visit our website to find out more, and sign up to our newsletter to keep up to date with our latest news.